"I'm building a wall, a fine wall/Not so much to keep you out, more to keep me in." -Pet Shop Boys "Building A Wall"

Close to being completed. Sheeting today and paint tonight.

Here's a side view drawing of what is going to be 50'+ of seating for a new restaurant by the name of Haiku on the Drake campus. Plywood? Hell no. The backrests and seats on this installation will be solid 5/4 white oak.

Here's a side view drawing of what is going to be 50'+ of seating for a new restaurant by the name of Haiku on the Drake campus. Plywood? Hell no. The backrests and seats on this installation will be solid 5/4 white oak.

Today's post is an update on the shelving being fabricated for ISU Dining in the newly renovated Oak/Elm Hall. Check out this entry from a couple of weeks ago for a drawing of the design.

Today's post is an update on the shelving being fabricated for ISU Dining in the newly renovated Oak/Elm Hall. Check out this entry from a couple of weeks ago for a drawing of the design.

Thanks goes out to Eric at Colony Heating and Air Conditioning for busting these oak and elm leaves out for me on Monday. Fast turnarounds rule. The leaves will be cold forged and welding to some vineyard bar under the shelf, running the length of the fixture. Again, go back to the drawing for a clearer explanation.

Thanks goes out to Eric at Colony Heating and Air Conditioning for busting these oak and elm leaves out for me on Monday. Fast turnarounds rule. The leaves will be cold forged and welding to some vineyard bar under the shelf, running the length of the fixture. Again, go back to the drawing for a clearer explanation. After not being able to find the shorty tri-pod my wife threw away, I improvised with a 1/4 x 20 bolt, Vise-Grips and my Jawhorse. For what? As if fabrication pictures aren't boring enough, I've been recording footage of myself in the highly entertaining act of fabricating on my Flip for a compilation video of this ISU job. We'll see how it turns out after installation is complete and I can edit all the clips together. I'm having a hard time coming up with an accompanying tune to go with welding, grinding, drilling etc....Any suggestions?

After not being able to find the shorty tri-pod my wife threw away, I improvised with a 1/4 x 20 bolt, Vise-Grips and my Jawhorse. For what? As if fabrication pictures aren't boring enough, I've been recording footage of myself in the highly entertaining act of fabricating on my Flip for a compilation video of this ISU job. We'll see how it turns out after installation is complete and I can edit all the clips together. I'm having a hard time coming up with an accompanying tune to go with welding, grinding, drilling etc....Any suggestions?

I finished fabrication on this barn wood shelf on Friday. The books were inlaid about two inches deep to a snug fit without requiring any adhesive or fasteners. All that's left to do is construct an apparatus to hang the shelf on to give it a floating appearance. This particular piece is for my folks to replace my mother's outdated P. Buckley Moss ('80s anybody?!) prints. I can't wait to hang it for the two of them.

I finished fabrication on this barn wood shelf on Friday. The books were inlaid about two inches deep to a snug fit without requiring any adhesive or fasteners. All that's left to do is construct an apparatus to hang the shelf on to give it a floating appearance. This particular piece is for my folks to replace my mother's outdated P. Buckley Moss ('80s anybody?!) prints. I can't wait to hang it for the two of them.

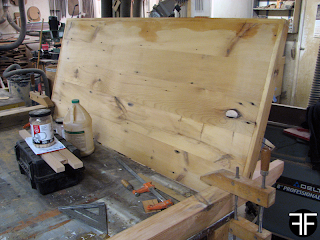

Coffee table above is 20" x 36" and about 18" tall. The lower section of the table will accommodate a shelf that I glued up earlier in the day. Entirely constructed of reclaimed barn wood with pinned, mortise and tenon joinery.

Coffee table above is 20" x 36" and about 18" tall. The lower section of the table will accommodate a shelf that I glued up earlier in the day. Entirely constructed of reclaimed barn wood with pinned, mortise and tenon joinery. Both tables that will be for sale at Jazz In July art show on Tuesday.

Both tables that will be for sale at Jazz In July art show on Tuesday. Here's a bent wood, laminated coat rack constructed of maple, walnut and faced with zebrawood. Two gussets will be mounted right behind the face of the rack, just right and left of center. They will then meet on a lower mounting plate that attaches to the wall approximately 36" below the coat rack. The mounting holes are spaced 48" on center making installation into two studs easy...as long as you find them.

Here's a bent wood, laminated coat rack constructed of maple, walnut and faced with zebrawood. Two gussets will be mounted right behind the face of the rack, just right and left of center. They will then meet on a lower mounting plate that attaches to the wall approximately 36" below the coat rack. The mounting holes are spaced 48" on center making installation into two studs easy...as long as you find them.

Above is a mock-up of one of two end tables for our house. Bethany and I picked out a piece of zebrawood last night at Woodsmith Store. The grain orientation can be really wild at times and makes power-planing difficult as the wood develops checking and chatter marks quite easily. I'll have my buddy, Toby, run these through his wide-belt sander to surface the tops. The frames are 1" square tubing that's been rusted and sprayed with polyurethane.

Above is a mock-up of one of two end tables for our house. Bethany and I picked out a piece of zebrawood last night at Woodsmith Store. The grain orientation can be really wild at times and makes power-planing difficult as the wood develops checking and chatter marks quite easily. I'll have my buddy, Toby, run these through his wide-belt sander to surface the tops. The frames are 1" square tubing that's been rusted and sprayed with polyurethane.

This is one of two reclaimed barn wood tables. The 1 1/2" thick table tops measure 20" x 36", with the one pictured above standing 34 1/2". Both are constructed with pinned mortise and tenon joinery, as shown below. The other table will be coffee table height.

This is one of two reclaimed barn wood tables. The 1 1/2" thick table tops measure 20" x 36", with the one pictured above standing 34 1/2". Both are constructed with pinned mortise and tenon joinery, as shown below. The other table will be coffee table height.

It seems like I'm building everything in pairs these days, and this shelf is no exception. The books are actually going to be recessed into the wood and act as "book" bookends. The spines will be set back (as shown) so the recessed couple of inches won't be seen. These were inspired by Juxtaposed:Power from Blankblank. I can assure you mine won't be $3K...no kidding, follow the link.

It seems like I'm building everything in pairs these days, and this shelf is no exception. The books are actually going to be recessed into the wood and act as "book" bookends. The spines will be set back (as shown) so the recessed couple of inches won't be seen. These were inspired by Juxtaposed:Power from Blankblank. I can assure you mine won't be $3K...no kidding, follow the link.

Looking in my rearview mirror while leaving the shop, I had to pull over and take some pictures. This was around dusk, 8:56 p.m., as a nasty cell was rolling in...

Looking in my rearview mirror while leaving the shop, I had to pull over and take some pictures. This was around dusk, 8:56 p.m., as a nasty cell was rolling in...