"Yes, good day, Terry!"

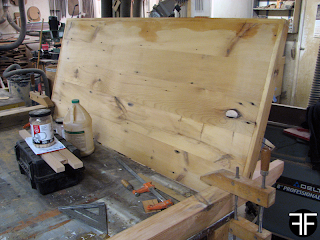

"Yes, good day, Terry!"Today was quite the productive and prosperous undertaking. Terry and I managed to demo what was-to-be the original counter substrate yesterday and build all the carcases for new cabinetry today. One 8' carcase and two at 42". The spaces in between will house a 4' reach-in cooler for the sushi chefs. Terry will be trimming all the faces in 3/4" x 1 1/2" red oak tomorrow.

But...and "listen to me now..."

This progress wouldn't have happened today if it weren't for Terry suggesting we "bring JG onto the job." JG is our trusty jobsite Craftsman table saw. Earlier in the year at the London Underground in Ames, we found JG next to an empty Miller Lite keg in the basement one morning. Yeah, he may have had a few pints the night before, but he performed like a champ that day.

Funny, JG is just where you'd expect to find him - bellied up to the bar. Too bad nobody told him the Miller guy has yet to drop off any inventory...

GOOD DAY!

Here's a side view drawing of what is going to be 50'+ of seating for a new restaurant by the name of Haiku on the Drake campus. Plywood? Hell no. The backrests and seats on this installation will be solid 5/4 white oak.

Here's a side view drawing of what is going to be 50'+ of seating for a new restaurant by the name of Haiku on the Drake campus. Plywood? Hell no. The backrests and seats on this installation will be solid 5/4 white oak.